Gloucester Drawbridge Replacement October 2021 Progress Recap

Updated on November 19, 2021

The MBTA is pleased to provide an update on ongoing and completed project activities, as well as a preview of upcoming work.

Although the project remains on schedule, supply chain delays and bridge construction complexities have delayed the opening of the southern barrel. As we evaluate alternatives to restore rail service as soon as possible, work crews are using this opportunity to accelerate other projects planned for the line. We’ll notify the project email list and the local press when a new reopening date is available.

Building a Better T

As part of our $9.6 billion, 5-year capital investment plan, we're renovating stations, modernizing fare collection systems, upgrading services for our buses, subways, and ferries, and improving the accessibility of the entire system.

Control Tower

Workers continue to prepare the control tower to operate the new bridge. Roofing panels are being installed over the observation level of the tower, and plumbing is being installed within the control level.

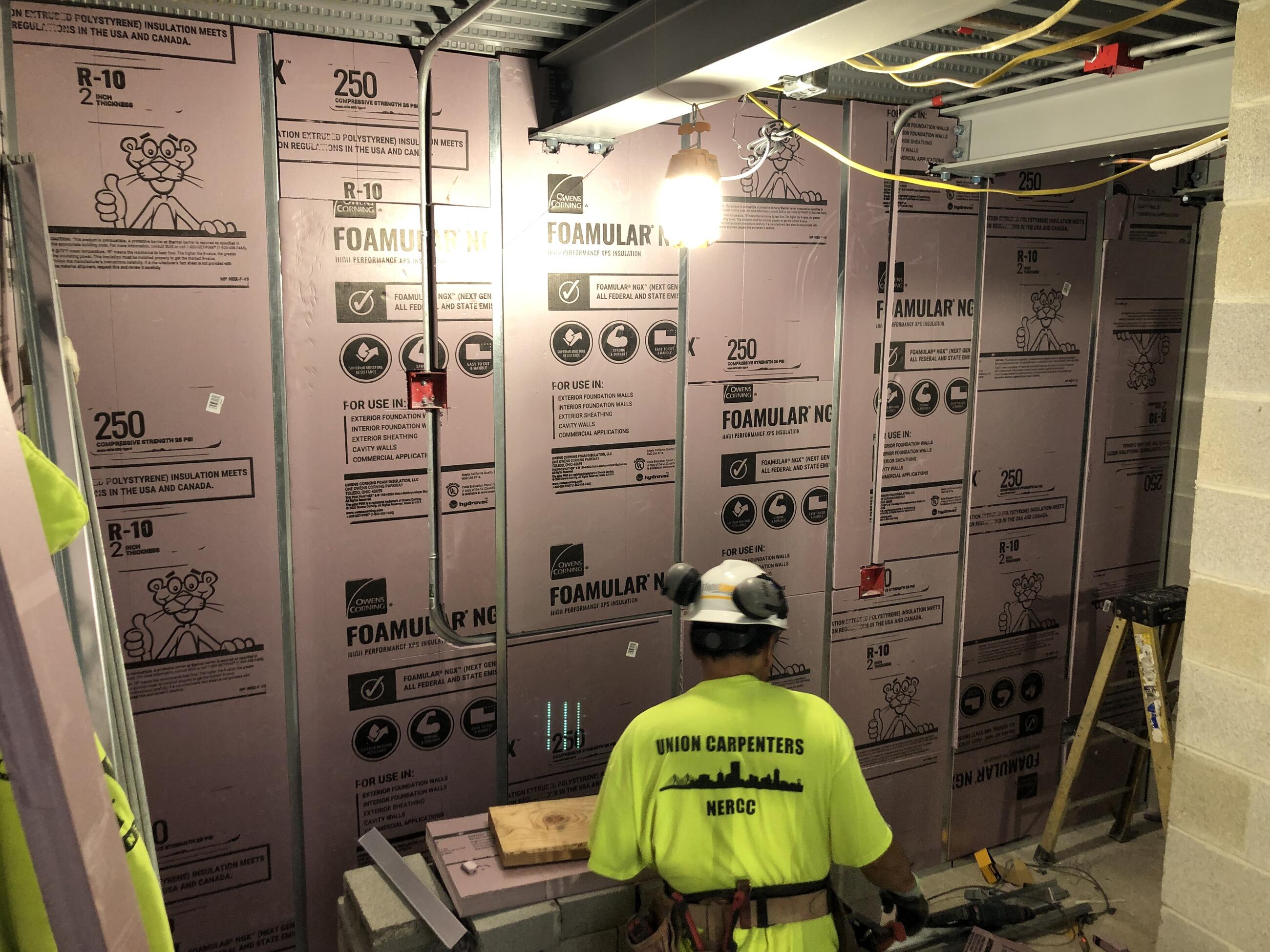

Workers are preparing the interior of the control tower for drywall installation.

Piers 2 and 3

Precast footing panels are being installed at Piers 2 and 3. The formwork is being removed from the previously constructed south footing so that existing footings on the north side can be connected.

Precast poured-concrete panels for the footings have been delivered to the site and installed.

We are installing a fender system in the channel to protect the bridge from damage caused by vessels moving underneath.

Signals, Power, and Utilities

Crews have begun pretesting control tower operation of the bascule span. They are operating the bridge using the main drive and control panel during testing. Continuing installation of the signal system includes connecting all signal instrument houses and signal instrument rooms together.

Workers are also installing the framework for the walkways around the signal instrument rooms and the control tower.

Upcoming Work

- Continued installation of drywall, electric service, and plumbing inside the control tower

- Continued fender system installation

- Witness testing of the new equipment and systems

For More Information

If you have questions or comments, please email the team at GloucesterDraw@MBTA.com.

Related Projects

Building a Better T

As part of our $9.6 billion, 5-year capital investment plan, we're renovating stations, modernizing fare collection systems, upgrading services for our buses, subways, and ferries, and improving the accessibility of the entire system.